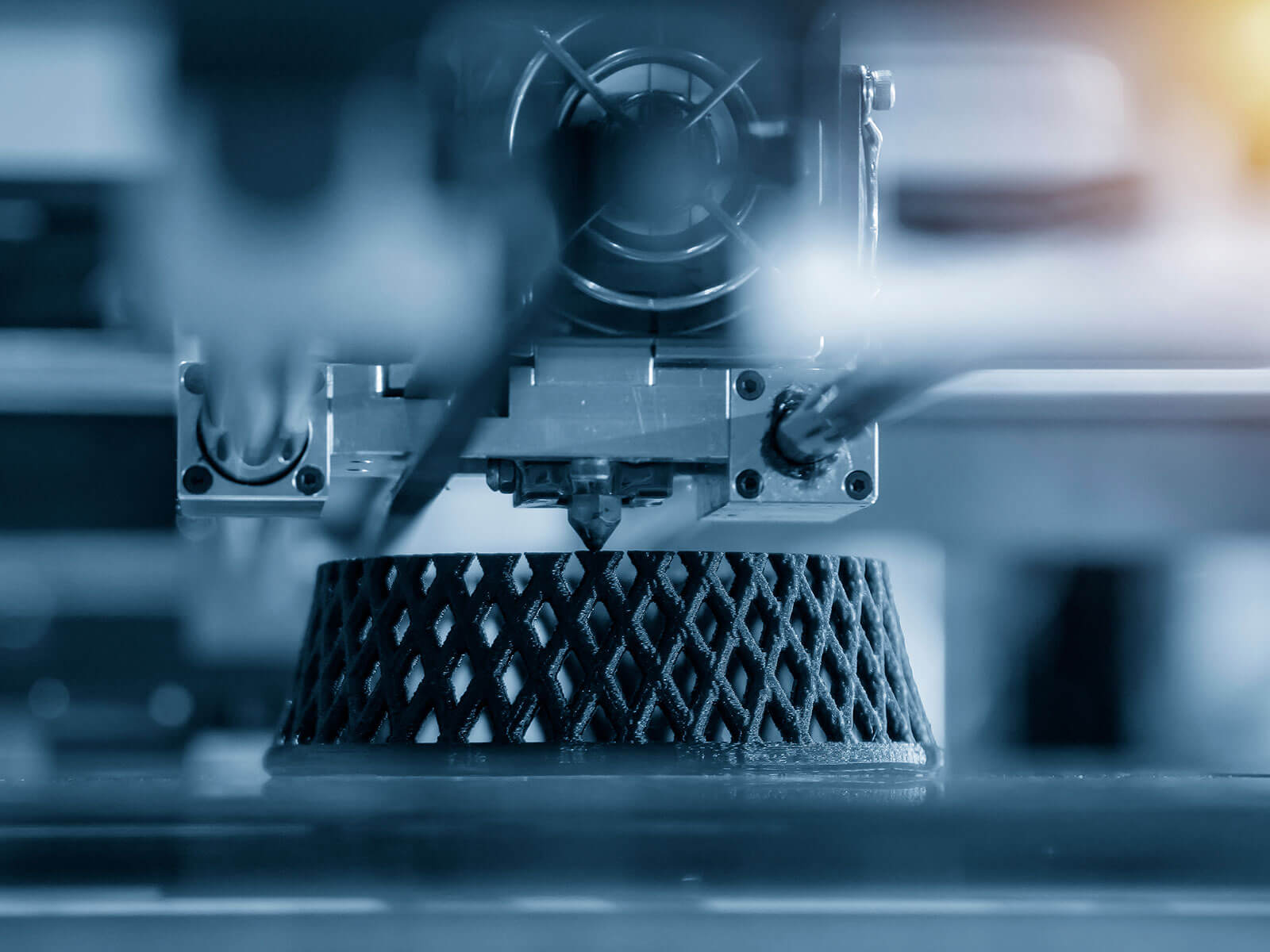

3D printing includes a variety of different manufacturing technologies. These technologies can be divided into two; a material is applied layer by layer and material is in powder form and bonded layer by layer.

Advantages of manufacturing with 3D printing

- Flexibility in production: Makes economic sense from batch size 1; product changes are possible at almost any time.

- Speed: Shortening of the development process and “to-market” time.

- Design freedom: Almost no more design restrictions and individual product design possible.

- Efficiency: Low material consumption and very low storage requirements due to almost just-in-time production.

New business models for 3D printing

An important component of the democratization of production is 3D printing service providers. This will make production more local, faster and more flexible again, especially for SMEs and start-ups, but also for everyone else. New companies and business models are also emerging in developing and supplying 3D models and in the software sector.

3D printing process chains

3D printing also has an impact on global process chains by making them shorter and regionalized again. This brings production closer to the point of consumption. Regionalization and decentralization will also make it possible to respond more quickly to changing customer requirements. Warehousing is also almost superfluous, as products are produced when they are needed.

Sustainable 3D printing

The possibility of producing more sustainably is closely linked to regionalization and the shortening of process chains. In almost every step of the 3D printing process chain, 3D printing makes a notable contribution to sustainability:

- Pre-production: almost no tools are required.

- Production: A partly drastic reduction in the number of components.

- Warehousing: Less material consumption, fewer logistics required.

- Product design: weight and shape optimization, lower energy, and material consumption.

- Service and maintenance: spare parts are manufactured when needed, and inventory and component maintenance can be significantly reduced.

3D printing has opened up endless possibilities to improve a product, generating significant growth in the industry.